Ice machines are hardly a hot new technology. John Gorrie, an American physician, first built one in 1844 to cool the air for yellow fever patients. Today, they are widely used in hotels, schools, restaurants and other commercial facilities. These ice machines make a lot of ice. Hotel guests, for example, use roughly five pounds of ice per room each day. They also use a significant amount of energy and water, giving you an opportunity to take some serious heat off your utility bills.

The scoop on ice machines

Ice is available as cubes, flake or nuggets. A spinning auger inside a barrel-shaped evaporator scrapes ice off the sides into a storage bin to make flake ice. Nuggets are balls or clumps made from compressed flake ice.

Ice machines may be plugged in or hard-wired, and they’re categorized in several different ways. Commercial ice makers can be classified as either batch-type (also called cube-type) and continuous-type (flake or nugget). There are three main ice machine configurations:

- Ice-making head: The ice-making mechanism and the condensing unit in a single package, typically mounted on top of a separate ice storage bin. It’s modular in that you can combine different capacity heads with different storage options.

- Remote condensing unit: The ice-making mechanism and condenser or condensing unit are in separate sections.

- Self-contained or undercounter: The ice-making mechanism and storage compartment are in an integral cabinet. They are typically smaller capacity units and may have an ice dispenser for cups.

Ice machines can be either air-cooled or water-cooled. Air-cooled units need a lot of cool surrounding air to operate efficiently. A warm environment, such as 90°F or 70°F water, reduces output. Water-cooled units use 100 gallons of water for each 100 pounds of ice produced. While water-cooled units use less electricity (no cooling fans), the savings are often offset by increased water supply and wastewater costs.

Cool savings

Ice machines can really take a chunk out of your operating budget. By installing ENERGY STAR®-certified commercial ice makers, you can save on energy and water costs. ENERGY STAR units are, on average, 15% more energy efficient and 23% more water efficient than standard models.

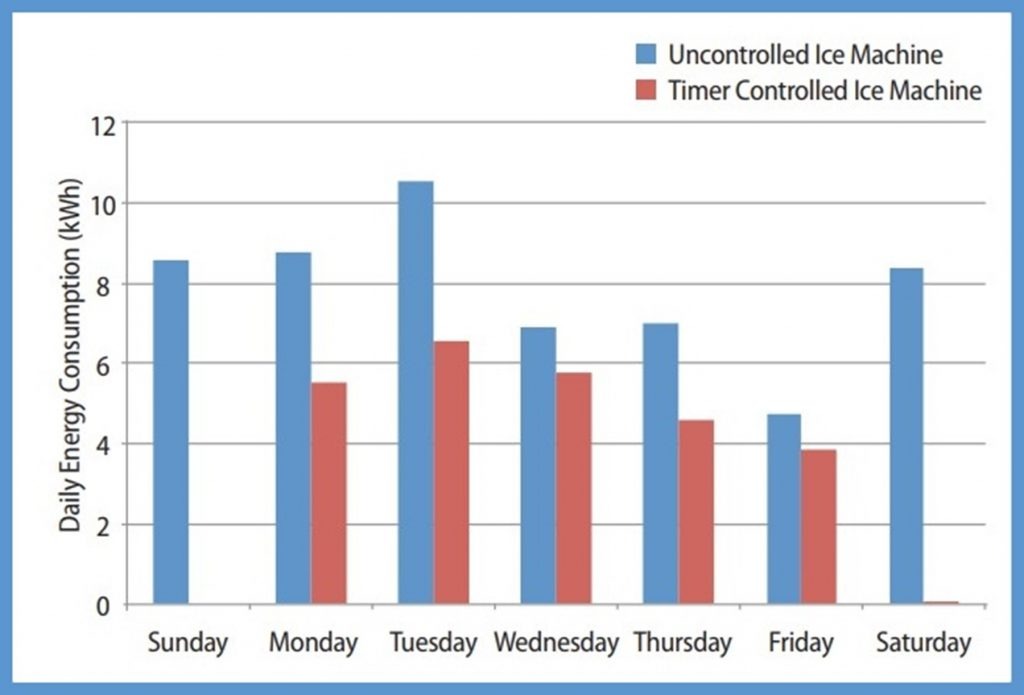

In some cases, merely installing a timer can significantly reduce ice machine energy use. The National Renewable Energy Laboratory (NREL) studied a food kiosk in three of its office buildings. The ENERGY STAR rated ice machines were controlled by electrical outlet timers to turn off during unoccupied hours, which reduced continuous power draw from 327 W to 110 W each.

The following chart compares measured daily energy consumption for an ice machine before and after timer control was implemented.

Nearly $150 per year was saved by installing a $20 electrical outlet timer and building occupants still had all the ice they needed.

With these measures, you can cut into your energy and water supply costs. For more information on how much you can save, see the U.S. Department of Energy’s Energy Cost Calculator for Commercial Ice Machines.