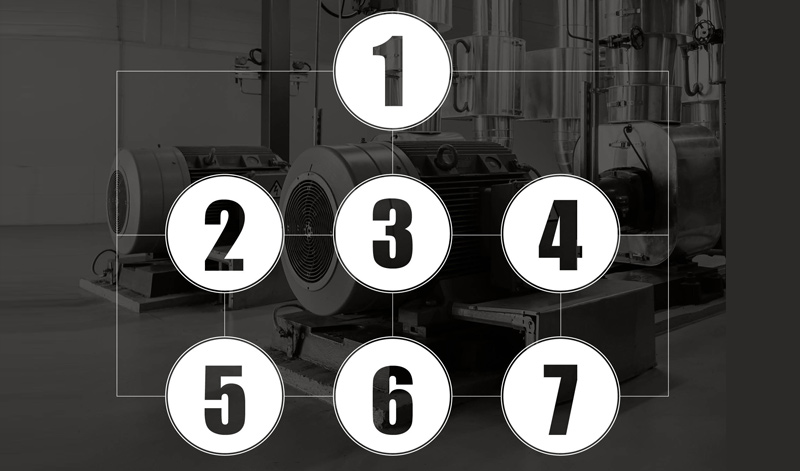

7 Steps to Improving Motor Performance

Motors are widely used in commercial and industrial facility, and they account for more than half of the electricity used nationwide. The U.S. Department of Energy (DOE) has identified seven motor performance improvement opportunities that address both component and system issues.

1. Address motor and drive system operating conditions

- Screen all motors to identify those that are essential and consume the most energy.

- Identify motor size and annual operating hours.

- Determine each motor’s load-duty cycle — the percentage of time that a motor operates at a given load.

2. Establish a motor management program

- Institute repair/replace and purchasing policies.

- Establish a motor and parts inventory.

- Track motor life.

- Implement a schedule for required maintenance.

3. Provide basic maintenance

- Preventive maintenance — inspection, insulation, resistance, balance and alignment

- Predictive maintenance — vibration, lubricant, thermography and electrical signature

4. Select the right motor

Match motor type to the application using the following characteristics:

- Horsepower and speed

- Torque classification

- Duty cycle

- Efficiency

- Voltage

- Enclosure type

5. Use variable frequency drives

- Identify torque (varying versus constant)

- Consider speed variation characteristics

- Choose between electrical and mechanical type

- Avoid inappropriate uses

6. Address in-plant electrical distribution and power quality issues

- Overvoltage and undervoltage

- Power interruptions

- Voltage unbalance

- Transients

- Harmonics

- Low power factor

- Electromagnetic interference (EMI)

7. Evaluate motor repair service centers

Use the DOE’s Service Center Evaluation Guide to determine a service center’s ability to perform quality work based on the following elements:

- Vendor market niche

- Tools and facilities available

- Repair materials used

- Staff experience and training

- Record keeping system

See the DOE sourcebook Improving Motor and Drive System Performance for detailed guidelines and practices for improving system operating efficiency and reliability.