Cooling Systems: 4 Hidden Energy Costs

Annual inspections of cooling system are essential to efficient operation. However, a closer look at the system and around the facility will likely reveal areas of waste and inefficiency that are adding to air conditioning system costs. Here are four things to watch out for.

1. Out-of-tune building controls

An energy management system is designed to optimize savings, but if just you set it and forget it, it can end up increasing energy costs. Occupancy and operating schedules often vary over time, and building controls must change accordingly. Adjust thermostats and other controls to save energy and maintain comfort. Calibrate sensors, valves and actuators in accordance with original design specifications.

2. Kitchen ventilation

For facilities with kitchen operations, the kitchen ventilation fans may be running at 100% capacity all day long. This not only wastes energy, it also makes HVAC systems work harder to supply makeup air. Install demand control ventilation, which saves energy by adjusting the fan speed automatically according to need.

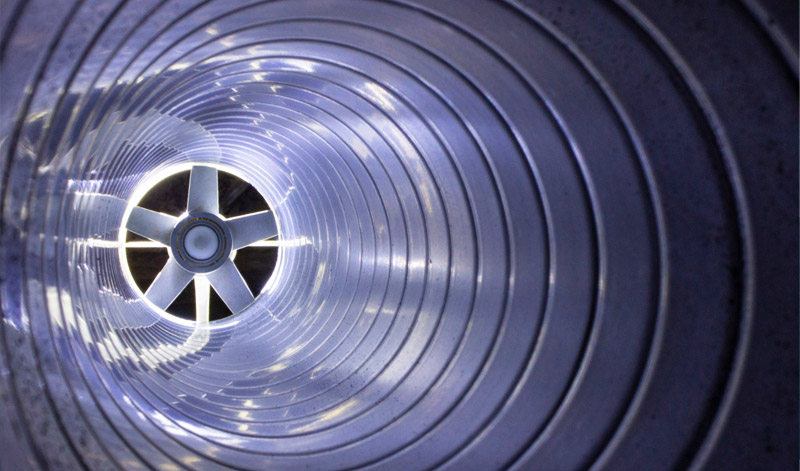

3. Leaky ductwork

Leaky ducts can lead to higher cooling costs. Although some leaks are easy to locate, test systems to identify the extent of system leakage by finding hidden losses. Those that are within reach can be fixed with mastic tape. Large-scale leaks can be sealed using aerosol technology, which blows tiny particles through the duct system, adhering to leaks and forming a seal.

4. Chilled water lines

Chilled water lines absorb heat from the surrounding air, reducing air conditioning system efficiency and performance. Insulating chilled water piping can help limit the amount of heat absorbed. It also guards against condensation. The type and amount of insulation depends on the temperature of the water running through the pipes.

Once you’ve identified and implemented opportunities to reduce operating costs, remember that preventive maintenance is the key to long-term savings. Merely fixing issues as they arise can lead to many of the problems described above. A sound preventive maintenance program is the best way to keep equipment operating at peak performance and keep energy costs down.