High-Performance Building Envelopes by Design

ANSI/ASHRAE/IES Standard 90.1-2016 Energy Standard for Buildings Except Low-Rise Residential Buildings provides minimum requirements for energy-efficient design of commercial buildings. Each revision emphasizes higher-performing wall assemblies and building envelopes. Continuous insulation and air barriers are two important practices that help achieve such performance.

The standard requires that the entire building envelope be designed and constructed with continuous insulation. This is defined as insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. Thermal bridges occur from wall studs and ceiling joists. Infrared thermography is used to evaluate thermal flow through a building envelope.

Measuring performance

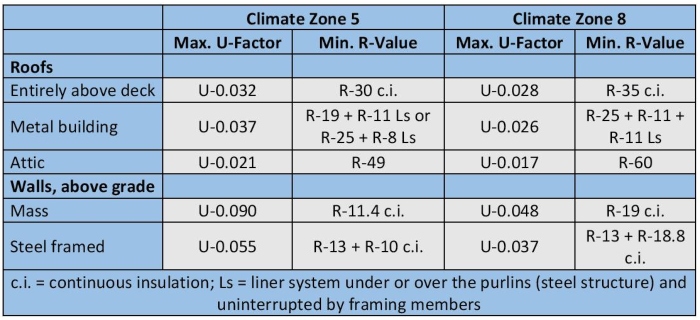

Insulation minimum R-values are listed in tables by eight U.S. climate zones. Climate Zone 1 is the warmest, while climate Zone 8 is the coldest. R-values are a measure of resistance primarily to thermal conductance and secondarily to thermal convection.

For non-opaque surfaces (walls and roofs), ASHRAE 90.1 Section 5 Building Envelope lists minimum R-values for insulation in framing cavities and/or continuous insulation separately or just one value for both. You can alternatively choose to meet the maximum U-factor for the entire assembly, a measure of heat flow. The following table shows some insulation R-value minimums and U-factor maximums for two climate zones.

Wrapping things up

Thermal convection is also slowed using continuous air barriers, which are not the same as vapor barriers. At all penetrations, the ASHRAE standard states that the air barrier shall be caulked, gasketed or otherwise sealed in a manner compatible with the construction materials and location.

ASTM E779 – 10 Standard Test Method for Determining Air Leakage Rate by Fan Pressurization requires building envelope testing at 75 Pa (0.3 inch H2O), roughly equivalent to a 25 miles per hour wind speed. The measured air leakage rate of the building envelope must not exceed 0.40 cubic feet per minute per square foot under the specified pressure differential.

Building codes rely on ASTM testing for the determination of both a material and assembly to be considered an air barrier. ASTM E2357 tests air barrier assemblies. There are several types of air barriers, each with pros and cons.

Sheet wraps are lightweight and fast and easy to put in place. However, they need sealant around penetrations and seams, require fasteners and can tear in the wind.

Peel and stick wraps are thicker, resistant to damage and easy to inspect. Despite these advantages, they are expensive and require shingling or overlaps around penetrations.

Liquid-applied membrane is easy and fast to install. However, installation can be dependent on weather and a long drying time is required. Also, additional installation accessories are necessary and the material costs are higher.

Making an entrance

In colder climate zones, ASHRAE requires that cargo doors and loading dock doors be with weather seals (typically vinyl-wrapped compressible foam block) to restrict air infiltration when vehicles are parked in the doorway.

The standard also requires that exterior building entrances must be protected with an enclosed vestibule. Applicability depends on climate zone and the square area of the building. Exemptions include climate zones 1 and 2, as well as entrances with revolving doors.