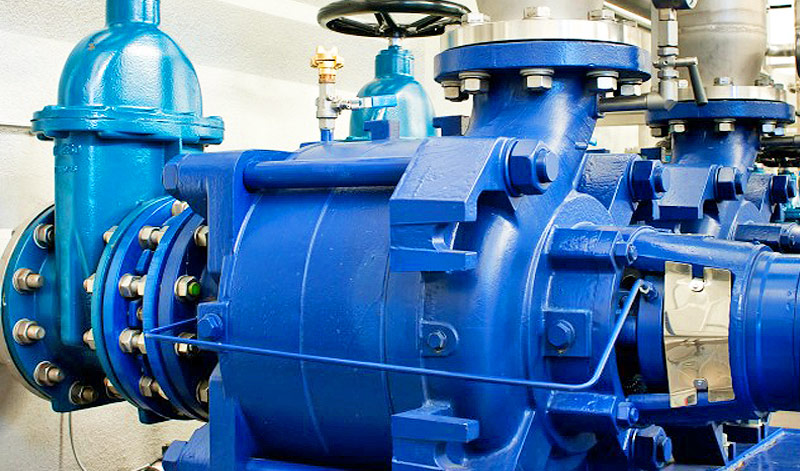

Smart Pump Systems Save Energy

Pumps are the workhorses in many commercial and industrial facilities, but they also use a lot of energy. An inefficient pump system can result in a significant amount of wasted energy that flows right onto your operating budget. Fortunately, a combination of advanced pump designs and intelligent controls can help your facility use energy smarter and more efficiently.

The problem with pumps

The pump’s job is to move liquids and solids. But the size of the pump system compared to the load and the way it operates are critical factors often overlooked. Consider the pump operating cycle, which varies substantially on a daily and weekly basis. Those variances translate into increased energy consumption and reduced system efficiency. Think of it like this: a typical process load varies depending on production needs. That’s why improved pump designs are being used to advance efficiency and mitigate the problem. As operating the pump becomes more economical, the total life cycle cost is reduced. Maintenance can also be a problem, especially for pumping systems used in boiler or chemical process applications. Partially clogged strainers or debris in the steam or fluid lines, demand ongoing maintenance. Without it, head pressure on the pump increases, resulting in higher energy consumption.

Variable frequency drives can help

Sometimes the pump system includes a variable frequency drive (VFD), which can help save energy and reduce system costs. This could occur when there is variable pressure or flow. Or, in the case of a pump that’s oversized, reducing the speed much of the time can correct the sizing and save energy. Finally, in a situation with variable loading and an oversized motor, the VFD can solve both problems. But VFDs offer additional benefits that should not be overlooked, like reducing mechanical stress, decreasing the need for maintenance and reducing inrush currents—all of which extend motor life.

The power of intelligent pump controls

The good news is, VFDs are getting smarter. Intelligent pump controls are equipped with digital control capabilities. The intelligence is embedded in the VFD, much like a programmable logic controller that gets embedded into the drive. This allows for several key benefits:

- Multi-pump systems are better managed, which means they can be measured, and operating cycles can be improved.

- Real-time data can be obtained by linking the pump to the building management system, offering yet another way to improve operations. Use of real-time diagnostic and prognostic information is used to automatically change the operation of a motor-pump system.

- Intelligent pump system controls provide better pump protection from pump blockage, cavitation and pump starting (dead head) problems. That translates into increased efficiency and reliability while increasing the life span of the pump.

- Certain conditions, including increased pressure, temperature or vibration, can be monitored to predict future maintenance needs.

- Output voltage can be regulated to improve system efficiency as loads change.

With benefits like reduced energy and maintenance costs, as well as longer equipment life, intelligent pump controls are a no-brainer for today’s commercial and industrial facilities.

Image source: U.S. Department of Energy